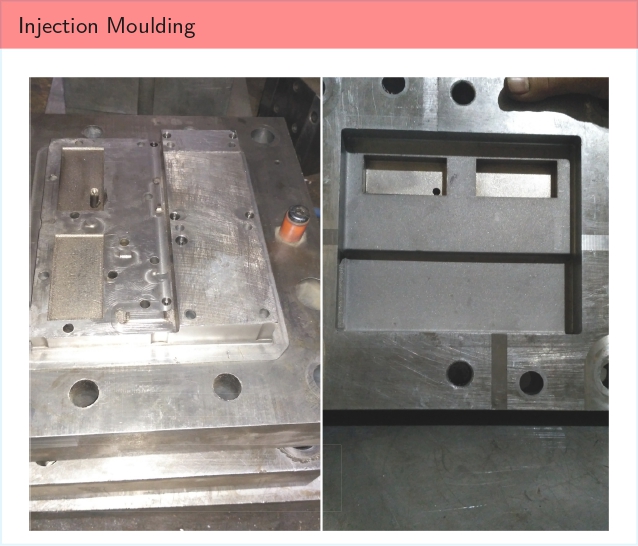

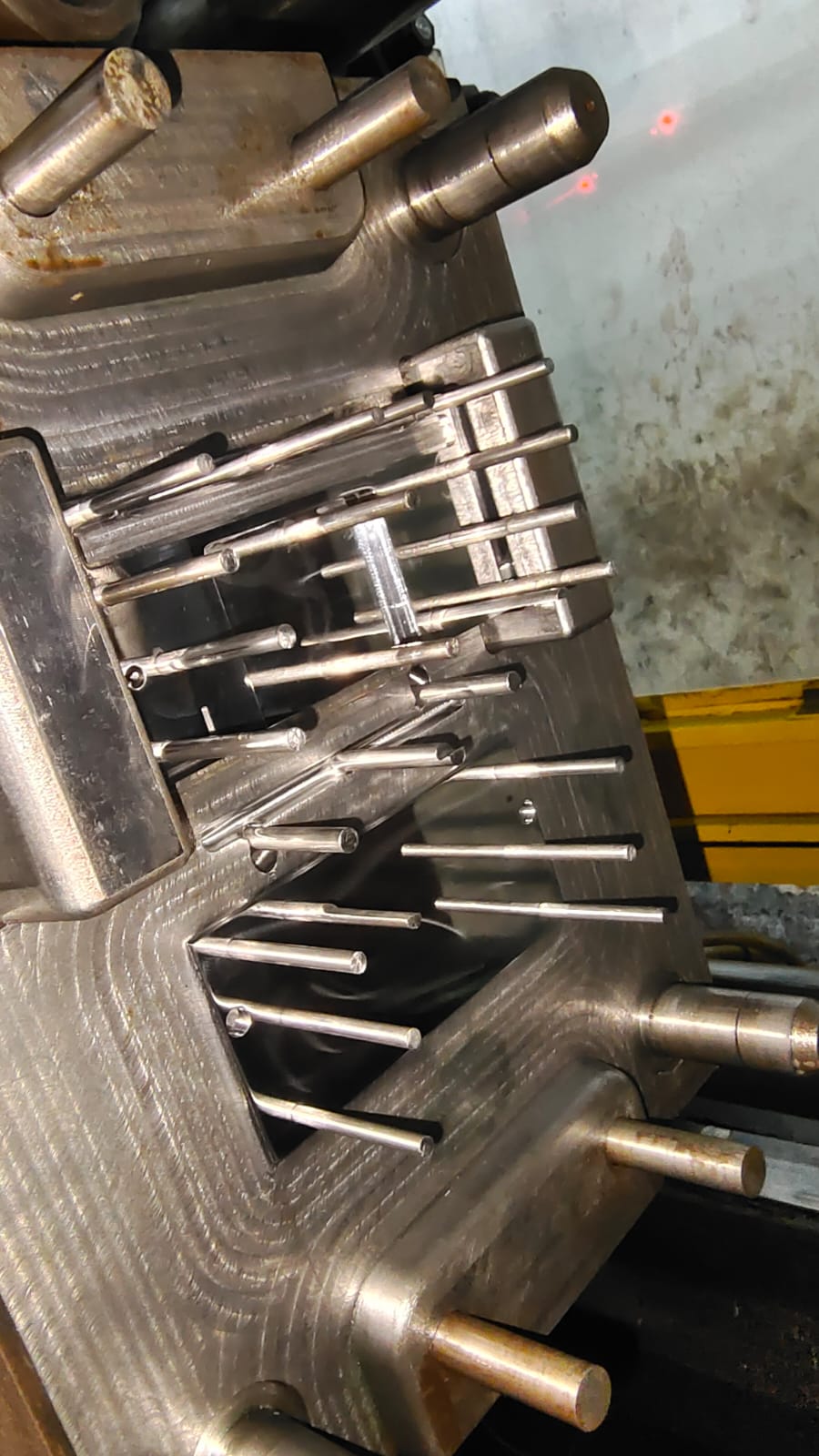

Injection Moulding

| Links:

I learnt CAD to design enclosures for the devices. These drawings were given to a wonderful moulding company called Paragon Products which prepared the moulds with their CNC partners, and supplied me with moulded parts

The proprietor Tushar Sood hires additional staff to modify my CAD designs to account for shrinkage, threaded holes etc, before going for CNC. Sharp corners and inserts are made with an EDM machine and copper bits at his factory. The surfaces of the mould are then either diamond polished for a glossy finish, or sandblasted for matte. Texturing can also be done with EDM, but is too expensive and i’m too poor.